Brookline Village Boat House

Tuesday, December 5th, 2017 @ 3:32 pm

black, boat, brookline, building, joinery, locust, mitch, outdoor, park, play, playground, ryerson, sculpture, timberframe

The second project I got to work on this summer with Mitch Ryerson was a boat house structure, dock, and boat for a playground in Brookline Village. It was a blast. This was a unique experience because we couldn’t get on site until way later in the season, so we spent the bulk of the time building and fitting what sections we could in his shop, which meant we had full use of machines and more typically (almost-)square (or what we began referring to as symbolically square) materials. We also made and used some real milled material for the floorboards, and to aid in more accurate exposed joinery on some of the bigger still-round pieces like the rafters and railings. This was an awesome fun thing to build, and I’m glad I got the opportunity to work on most of it.

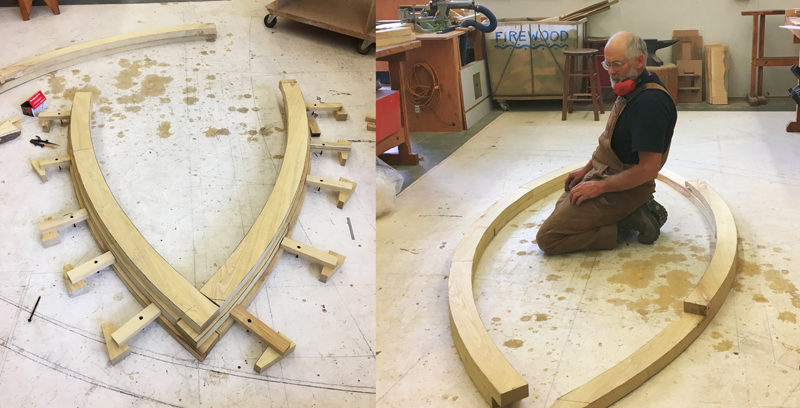

Starting into some funky curved, angled joints, and pre-fitting what we could in the shop.

Having a full-sized drawing on the floor was massively helpful for this project, as it allowed us to keep the huge pieces in a place that was easy to manage, and to move them around when we needed to, and we could just lay them on top of the template and trace the lines up from the floor to find our joinery. The tricky part came in when the pieces weren’t perfectly straight or square or flat, as they almost always weren’t. This meant we had to offset the starting location of the joint from the ending location of the joint, according to how much the pieces were offset from each other. It took some pretty weird tracin’ and figurin’ to line these things up and get the joints to fall into the right place. But they worked out in the end, and often times I feel that once I’ve sort of tackled and understood a new complicated thing, I don’t ever want to go back to doing things simpler. But that feeling usually abates around the end of the day. Until the next summer morning, and the next cup of coffee, and the next day in Mitch’s shop. Such a pleasure.

Notching the rafters for where they’ll eventually sit on the top plate. Started with a router jig and fine tuned each of them by hand, according to their places. Each one was a little bit different. Just like you and me.

This was a crazy joint to pull off, but we got two of them, and they came out great. It’s a lap joint, with a miter, and a through tenon from the post these pieces rest on top of. And one piece is at an angle. And so is the through tenon. Phew.

Some funky figurin’. I had to find the location of the end of one of the lapped pieces, and I couldn’t figure out another way than to lay it on a reliable surface and bring the measurement up and across. REALLY nice to have reliable work surfaces.

Once we got the bulk of the pieces cut, prefitted, and spaced out all the balusters, we brought most of that to the site and set some concrete footings into the ground. While the grounds crew did their landscape and hardscaping work, we got into the next part of the park: the boat.

Starting with another full-size drawing, we set the first course down, and got ready to block it up in layers from there.

Not building this like a typical boat, we opted to cut each piece from a curved template, with a bevel, all on the bandsaw, so the layers would sit together as closely to their final shapes and alignment as possible, minimizing the next step of grinding everything fair as much as possible. I stayed through the glued up and assembly of the halves, but wasn’t around for the fairing process, as I’d moved on to the MIT Museum from some prior commitments. But coming back to work with Mitch afterward in the late Fall, the halves came out beautifully and I’m proud of our methods in getting these things together. It just took time, lots and lots of sawdust, and a bunch of listening to podcasts.

Enjoying the process. Sometimes our accidents are fascinating.

The whole thing getting its last few pieces fitted and trimmed, and set in the sandbox on site.

While I was away, Mitch and another coworker Sam got the things put together and pegged, and we all brought the boat to the site and started in on laying out deck boards. Hopefully it’ll get a nice big cedar roof before winter comes. But for now, it’s sitting handsomely in place, fitting in nicely with the colors of its first New England Fall.

Update! 8/4/18

After the winter, we came back together to get this park finished up just in time for the big opening party that the town of Brookline hosted for the event. I took far fewer photos this season than last, but I got a few good ones.

Back to it.

Mitch bought some 8/4 cypress that we were able to resaw at an angle on his huge bandsaw in the shop to get these tapered clapboards which start at about 1/2″ and get wider to about 1-1/4″ or so. They’re then nailed into the rafters with big bronze ringshank nails and then riveted together with copper rivets at many more regular intervals. This stuff has seen quite a bit of rain already, and it’s been pretty effective at shedding it all onto the recycled bouncy rubber surface that now covers the blacktop around the structure. After all that work with the dense, heavy black locust, it was an absolute joy to lift and swing around these feathery cypress boards while standing atop the roof!

The only kind of shaving I’ve done in a long time.

Next up, we built the deck on the sand, burying some huge logs in the ground, bolted some smaller crosspieces onto them, and then sealing off (rat-proofing) all the interior spaces with chicken wire, and finally setting the planks on top and chamfering everything.

We installed some black locust lattice in all of the big openings that Mitch had made himself over the winter. The sections on the sides of the building had to curve because of the beams it would attach to, so he made the whole thing with the curve in it, since riveting that much and then bending wouldn’t probably have been possible. We added nailing strips and attached everything with big bronze nails. Some lattice we cut and installed in place because of the varying size and shape of the openings, riveting them together.

Freshly finished and ready for rain

We raced the weather on our very last day of building to get the last bits of epoxy fill, plugging and sanding and grinding done, and a good coat of finish on everything. Just as we finished up, the rain started sprinkling and gave our work a test.

We even had a moment to sculpt the sand into a wake of this little boat, heading off to sea.

Comments

Thoughts on the stuff you read? You can leave a response, or trackback from your own site.

Leave a Reply